Offshore charter party agreements are contracts that govern day-to-day operations, define fuel responsibilities, and can quietly drain budgets and relationships if not managed well. Yet, despite their strategic importance, many offshore charter track contracts are in many formats, leading to confusion, wasted time, and costly disputes.

As expectations around data transparency grow, it’s time to take a closer look at how these agreements work and how better data management can bring both charterers and shipowners closer to the same goals.

How Offshore Charter Contracts Really Work

a) Understanding offshore charter party agreements

Offshore charter contracts define the relationship between two key actors: the shipowner and the charterer. The shipowner provides the vessel, handles maintenance, and ensures the crew is available. The charterer is usually an energy company that leases the vessel for offshore operations. This partnership is common in oil and gas projects, where reliable logistics are essential.

But this relationship is not always straightforward. Each party has different responsibilities depending on the charter type. These responsibilities can impact everything from fuel usage to operational downtime. Misunderstandings can arise when data is missing or unclear. That’s why aligning both parties on contract terms and performance data is so important.

Here are some key aspects that define this relationship:

- Responsibility for fuel: Who pays depends on the charter type.

- Time on hire vs. off hire: This affects cost distribution.

- Maintenance windows: These can interrupt operations and shift obligations.

- Weather-related delays: These trigger different clauses.

- Remaining On Board (ROB) fuel and fresh water: Reconciliation at contract end often causes disputes.

Regarding the type of contracts, time charters are the most common. In this model, the charterer rents the vessel for a fixed period and pays for fuel. In a voyage charter, the shipowner covers most operating costs and receives a lump sum. Bareboat charters go further: the charterer takes full control, including crewing and maintenance.

Among these, time charters bring the most daily complexity. For instance, when a vessel is “on hire”, fuel and performance fall under the charterer. Costs are returned to the owner when the “off hire” is due to maintenance or delays, . Then comes the ROB reconciliation. This process determines who pays for the fuel left onboard at contract end. It’s not as simple as returning a rental car with a full tank. And if the data is unclear, both sides may disagree.

Even with contracts in place, problems start when teams still track performance data manually. That’s the real issue.

b) The problem of non-digitized tracking

Too many operators are still relying on manual spreadsheets and PDF reports to keep track of contract performance. That might have worked when fleets were smaller and contracts simpler. But today, digitized solutions exist to assure the accuracy of it.

Non-standardized and digitalized tracking introduces all kinds of risks.

- Inconsistent formats: one log reports in hours, another in days.

- Different EFMS systems stream fuel data at varying intervals.

- Sensors do not always provide all the required data.

- A typo in a daily report may go unnoticed until the end of a project, when it becomes a billing dispute.

And most importantly, there’s often no clear way to measure whether both parties are meeting the contract’s operational objectives. What should be a shared performance dashboard becomes a set of disconnected views.

Why a Third-Party Framework Makes Sense

This is where third-party solutions can play a pivotal role. A neutral, data-structured interface that ensures both charterers and shipowners’ access to the same KPIs, the same timelines, and the same language.

With a shared system :

- Fuel quotas and availability windows can be tracked

- Contractual clauses are no longer in a document but in a designed dashboard, with their operational filters and metrics.

- Engineers and vessel managers spend less time reconciling spreadsheets and more time optimizing fleet performance.

What Opsealog’s contract performance module offers

Opsealog developed its Contract Performance Module as a direct response to this industry gap.

Clients asked for a way to connect daily vessel operations to contractual obligations and quickly check how projects align with ON/OFF hire targets, fuel quotas, and availability goals.

Here’s how it works:

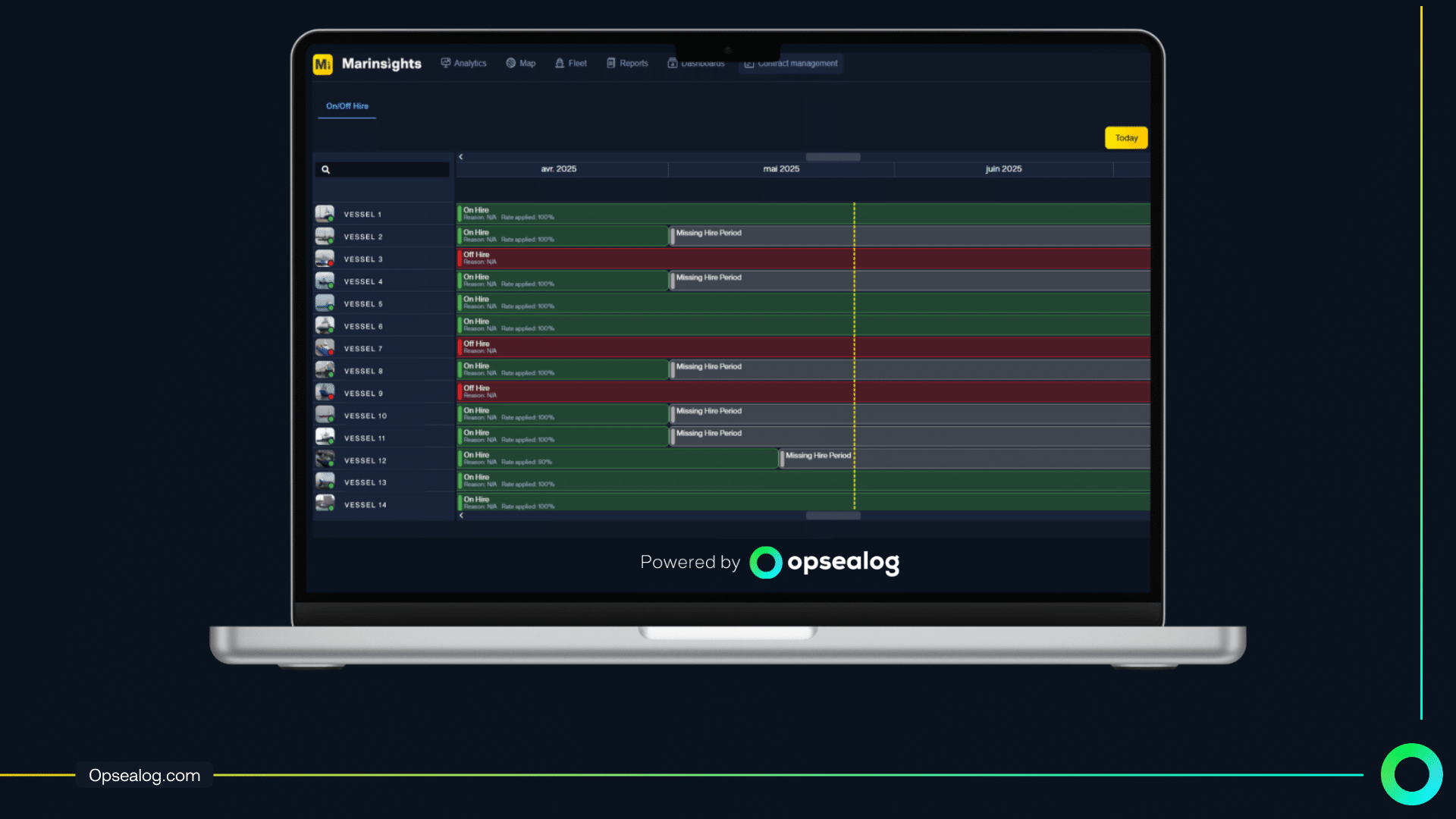

- Improved reporting of ON/OFF Hire and Maintenance & ROB Cost Reconciliation

Operations can now be directly linked to projects and contracts in the interface, with unified filters and improved reporting views to consolidate key data. - Clear allocation of contractual maintenance days

Visibility on how contractual maintenance days are counted and distributed across the on and off hire period - Better tracking of operational availability, fuel quotas, and vessel productivity

New dashboards and analytics provide visibility on fuel quota adherence, operational availability, and vessel use. - Actionable insights from a single, structured source

Users gain clarity on time spent ON Hire vs. OFF Hire, and how this compares to contract terms, helping them better assess performance and optimize planning - Personalization of Performance Targets

The module enables fine-tuning of contractual expectations per vessel or project, supporting adaptive planning and goal tracking.

Every metric required now lives in a structured, user-friendly, and interactive dashboard in Marinsights, our performance management application.

Why it matters now

This new module answers a growing demand from clients to connect daily operations with contractual obligations. Instead of scattered tracking and disconnected spreadsheets, they get a structured, interactive platform to monitor and report on what matters contractually.

With this module, Marinsights continues evolving into a platform that meets the growing demand for contractual accountability, fleet efficiency, and data-informed planning in offshore logistics. It was designed to reduce ambiguity, support decision-making, and help teams make better use of the data they already have.

The more it’s connected to operations, the easier it becomes to collaborate, track KPIs, and avoid end-of-project surprises.

Interested in how this module could apply to your operations?

Vincent Gomes, Senior Product Owner, and Briac Lemée, Business Development Manager, co-wrote this blog.